data-animation-override>

“21-year-old Tim Johnson set out to prove a point — one we think has been nailed home with his trophy-snatching RX-2”

Every year at the V 4&Rotary Nationals, there is that one car that stands out from the rest — its build quality, attention to detail, and overall bad-assery are just strides ahead of most other attendees. This year, that award (it’s not actually an award) would have to go to Tim Johnson’s Mazda RX-2, which won the crowds over following an 18-month ground-up build, finished only hours before the covers were pulled off at the show. Those 18 months had been a hard slog for the young man, working upwards of 80 hours a week, juggling between his day job as an apprentice mechanic earning cash to pay for the build, and progressing with the build itself. The hard slog paid off, earning Tim a swag of awards including the coveted RX Master, Best RX-2, Best Engine-Bay, Best Undercarriage and Suspension, and Best Display in open class. In fact, Tim expended so much effort completing the build, that his body simply shut down the following week. “I got glandular fever, tonsillitis, and strep throat. My body is still not right; but working 160 hours in 12 days will do that to you,” Tim told NZPC.

If you had asked Tim 18 months earlier whether he could see himself winning the RX Master at the 2015 Nationals, his reply would have been a definite “No.” You see, the build wasn’t really supposed to happen, at least not to the extent you see here. The RX-2 was a finished car when Tim purchased it, and a pretty nice one at that. “I had just finished modifying a VU HSV Maloo ute. It had a new exhaust, intake, fresh tune, and was slammed on adjustables, which made it a bit of a pig to drive. My brother took it for a drive and it was a bit damp — well, that car ended up written-off in a bank, so I started looking around at rotaries. I love their sound and how far people were taking their rotary builds. I found this RX-2 in Christchurch, and me and two mates drove there and back in one day,” explained Tim. The Series 2 sedan had originally been built in Wanganui by Chad Millbank, and had been through a few hands since Chad sold it. Thankfully, the bare metal respray chad carried out, had held up, and it had alright parts in the right places, including all the factory interior.

Tim knew it needed some work, but the bones were good, so he limped it back home to the Taranaki, complete with stuffed Series 4 gearbox, and a Hilux diff that was trying to shake the its arse off. Thankfully, it made it all the way back home without either component calling it quits. Tim wasted no time putting in work. “I basically took the entire engine bay apart in the second week I owned it, and went out to see the Raikes boys at Global Stainless. I started saying I wouldn’t mind getting this fixed and that polished. They were good bastards and said, ‘na, bring it all out and we will teach you how to do it.’ So I polished it all up, put it back together, and then a couple of weeks, and a few big burnouts later, it started to get hot. Because the gearbox and diff still needed to come out, I went all-in, balls deep.”

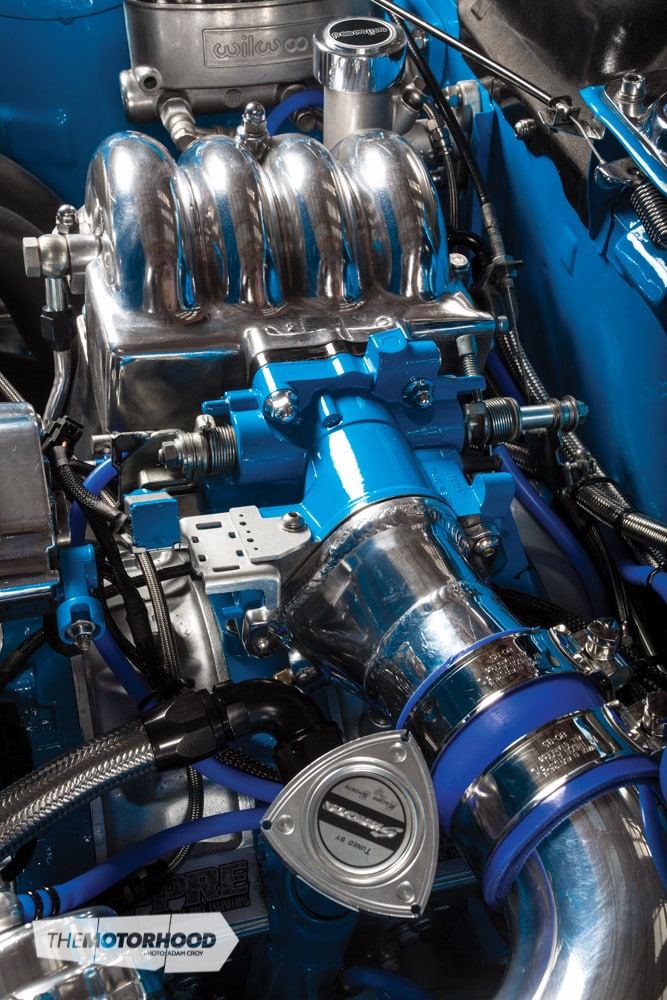

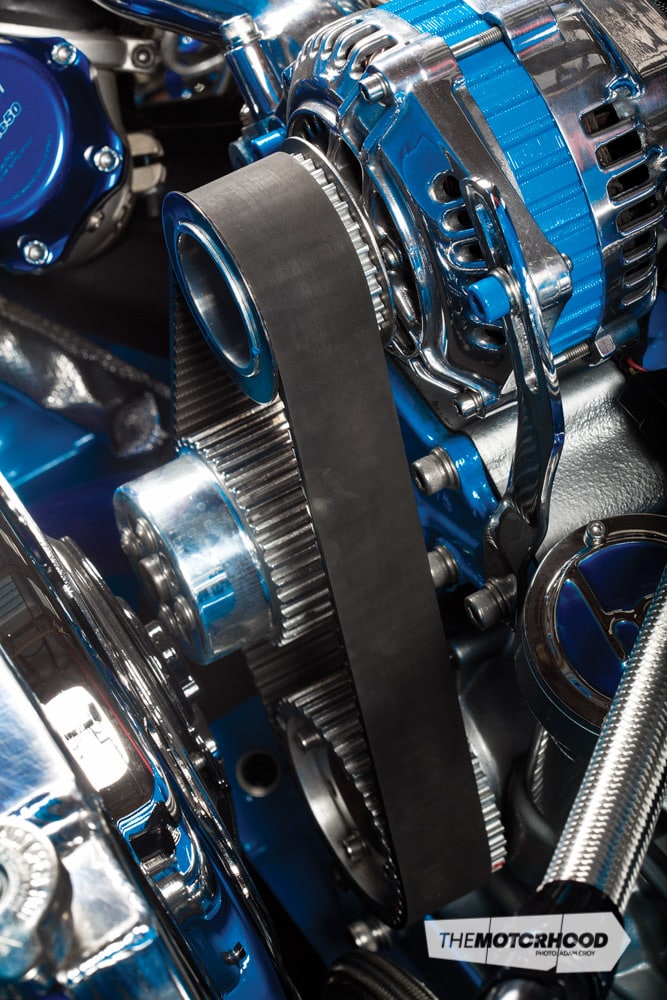

This would mark the beginning of an 18-month journey of week-in, week-out working, both day and night, to fund the car and get it finished. One of the first tasks was sorting out the engine. From the outset Tim wanted to have 373kW (500hp) on pump gas, and run a 10-second pass. The current suspect extend-port 13B was producing 260kW (350hp) at the wheels, so it needed to go. Fearing that a 21 year old wouldn’t be taken seriously over the phone, he made the trip to PPRE to discuss plans in person with Warren, who was confident that his team could make it happen. That afternoon, Tim left the workshop having purchased a 13B bridge-port block, E-boost controller and custom spec’d Master Power T70 turbo. The block had once lived in Glen Huijs’ NZPC 9-Second Club FC RX-7, and needed a new home. All the hard work so it could handle some boost had been done; the porting, stud kit, and oiling and high-rev mods. All that was needed was screwing the block together, a job PPRE handled using all new seals and gaskets.

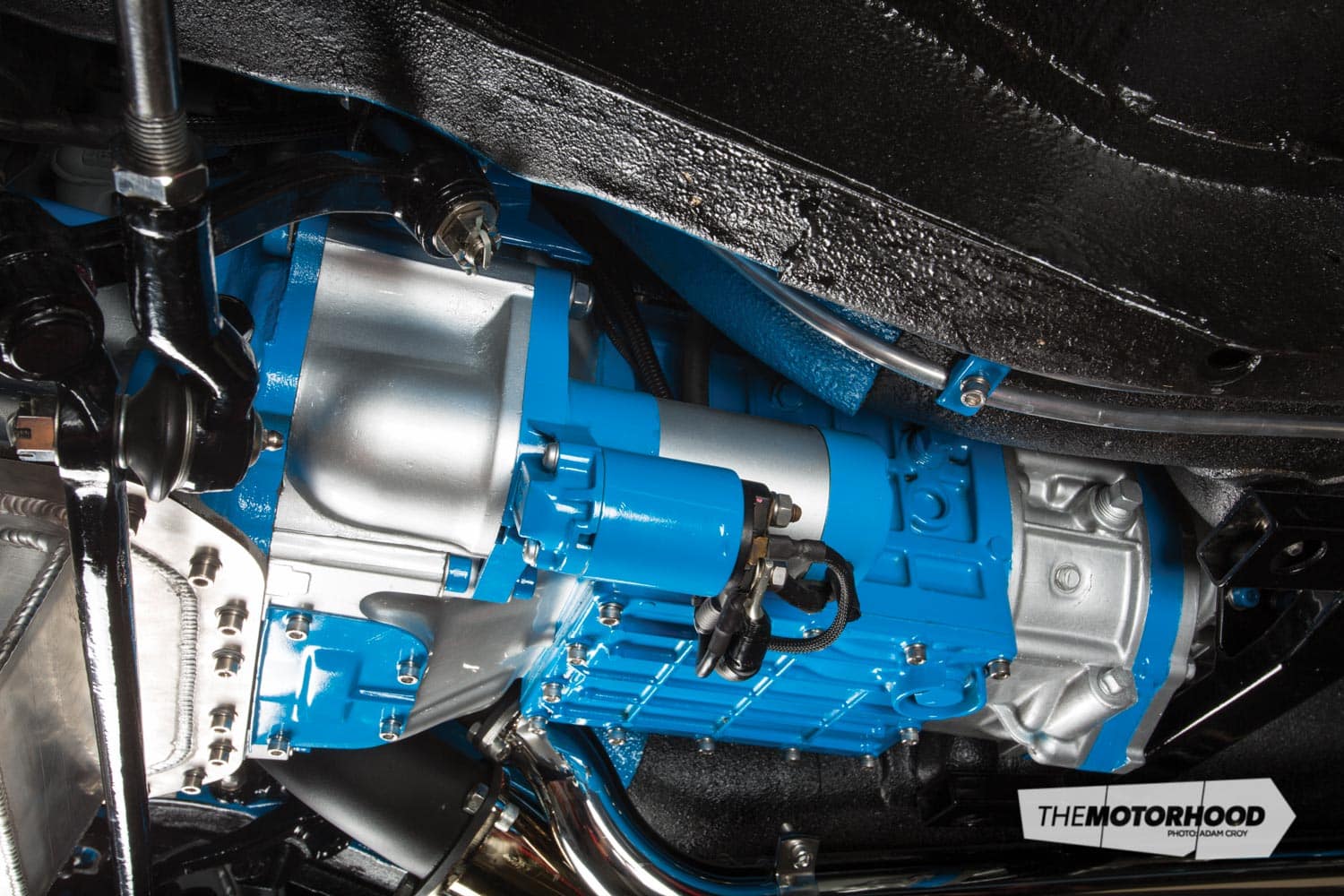

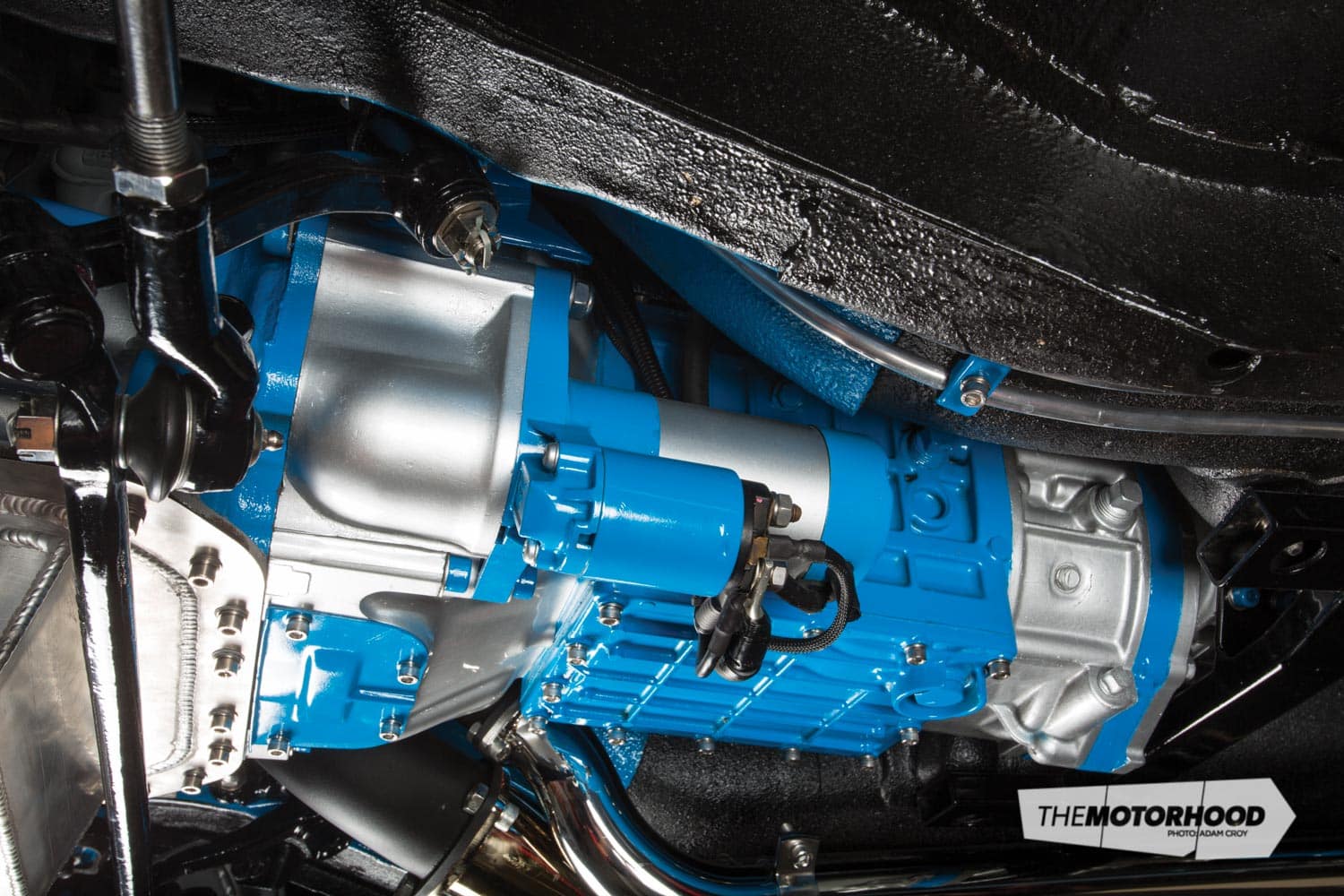

Backing the engine would be a Series 4 RX-7 gearbox that Tim had rebuilt with the help of a workmate. In fact, it’s one of three he has rebuilt, and once those are gone he will be looking into something a bit stronger. The 4.3:1 Hilux LSD has also been rebuilt, this time with the correct backlash, with the help of an ex-boss. For a young mechanic like Tim, it has been a good opportunity to upskill, and gets him closer to his goal of becoming a performance-car mechanic — not that this RX isn’t one hell of a CV in itself.

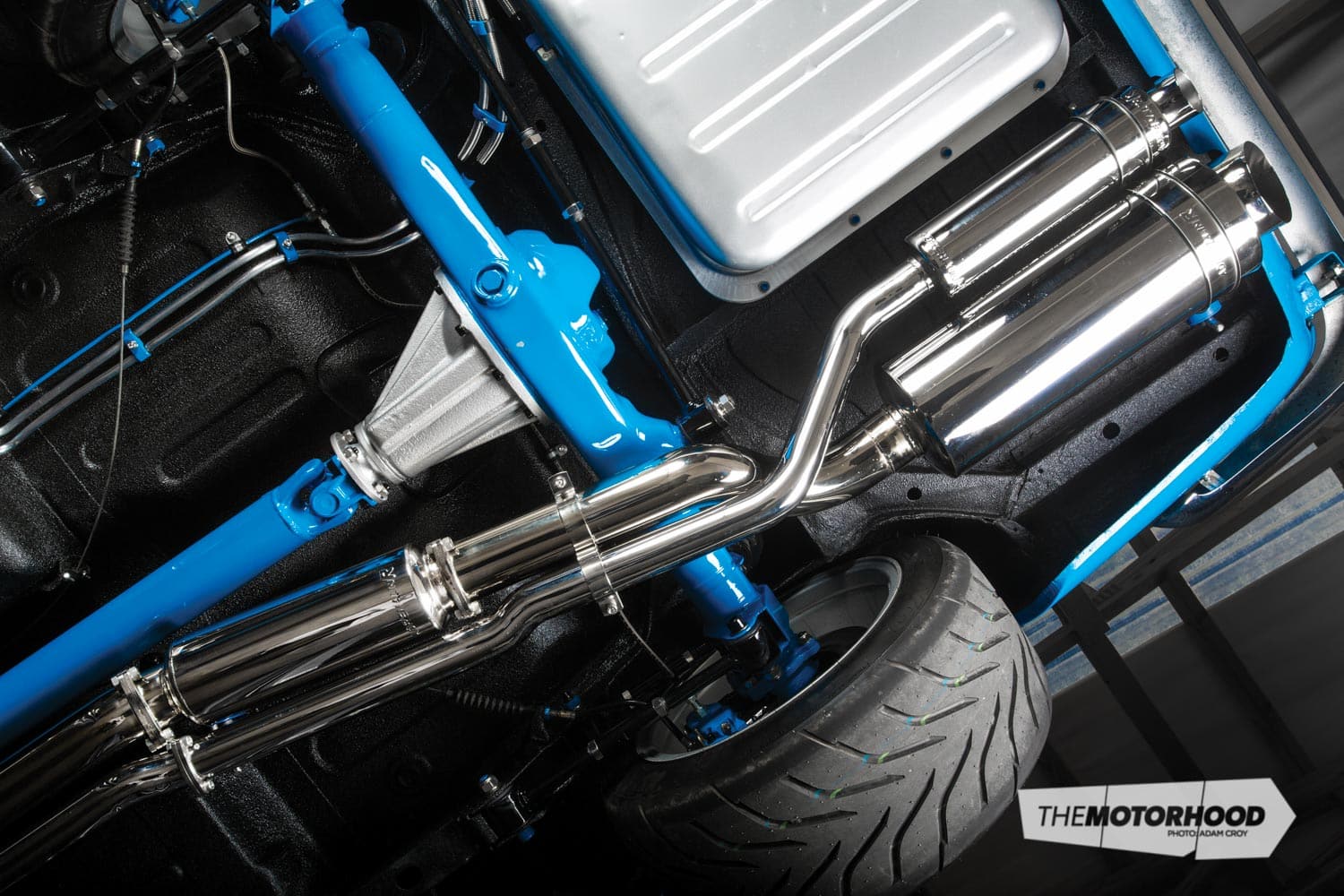

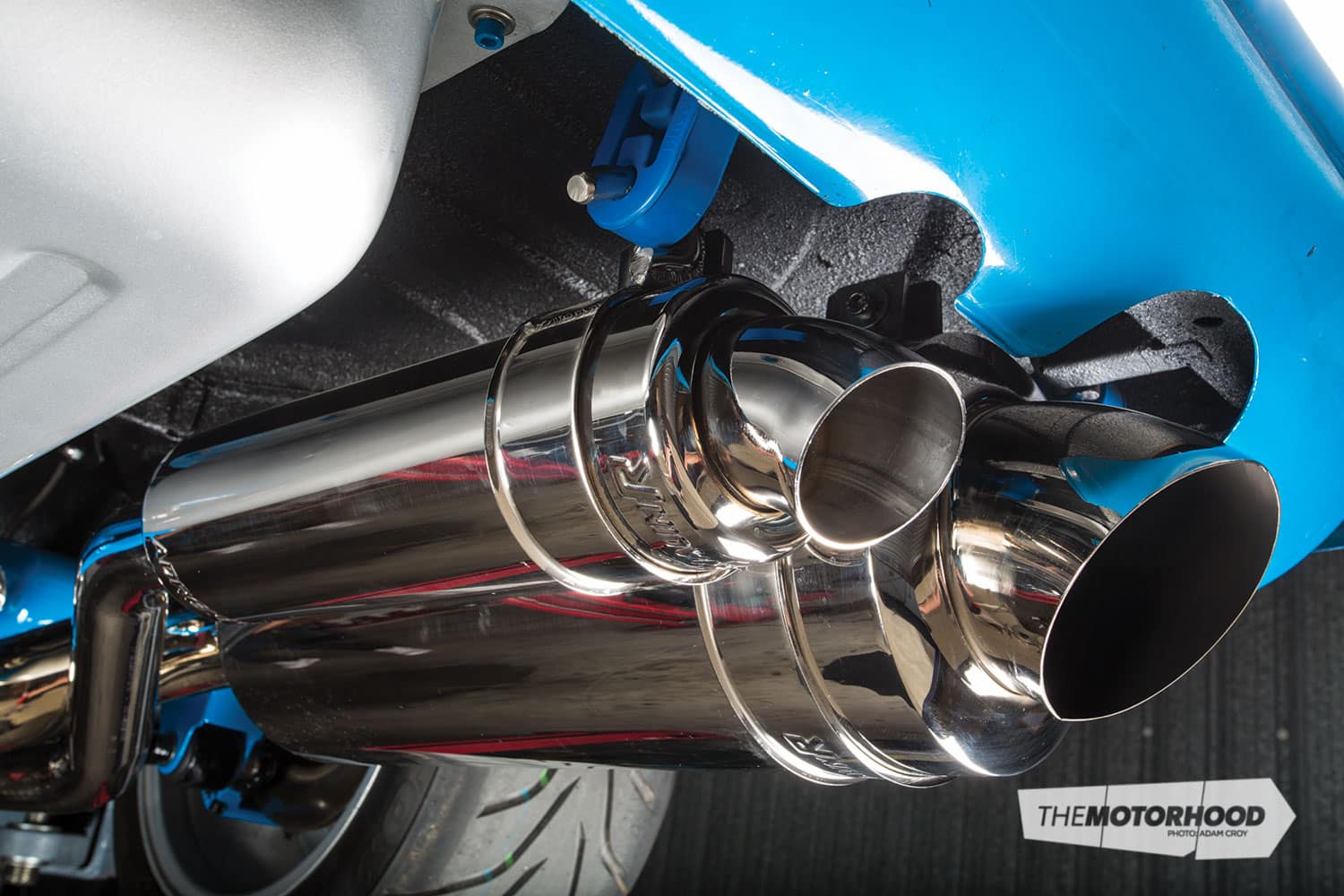

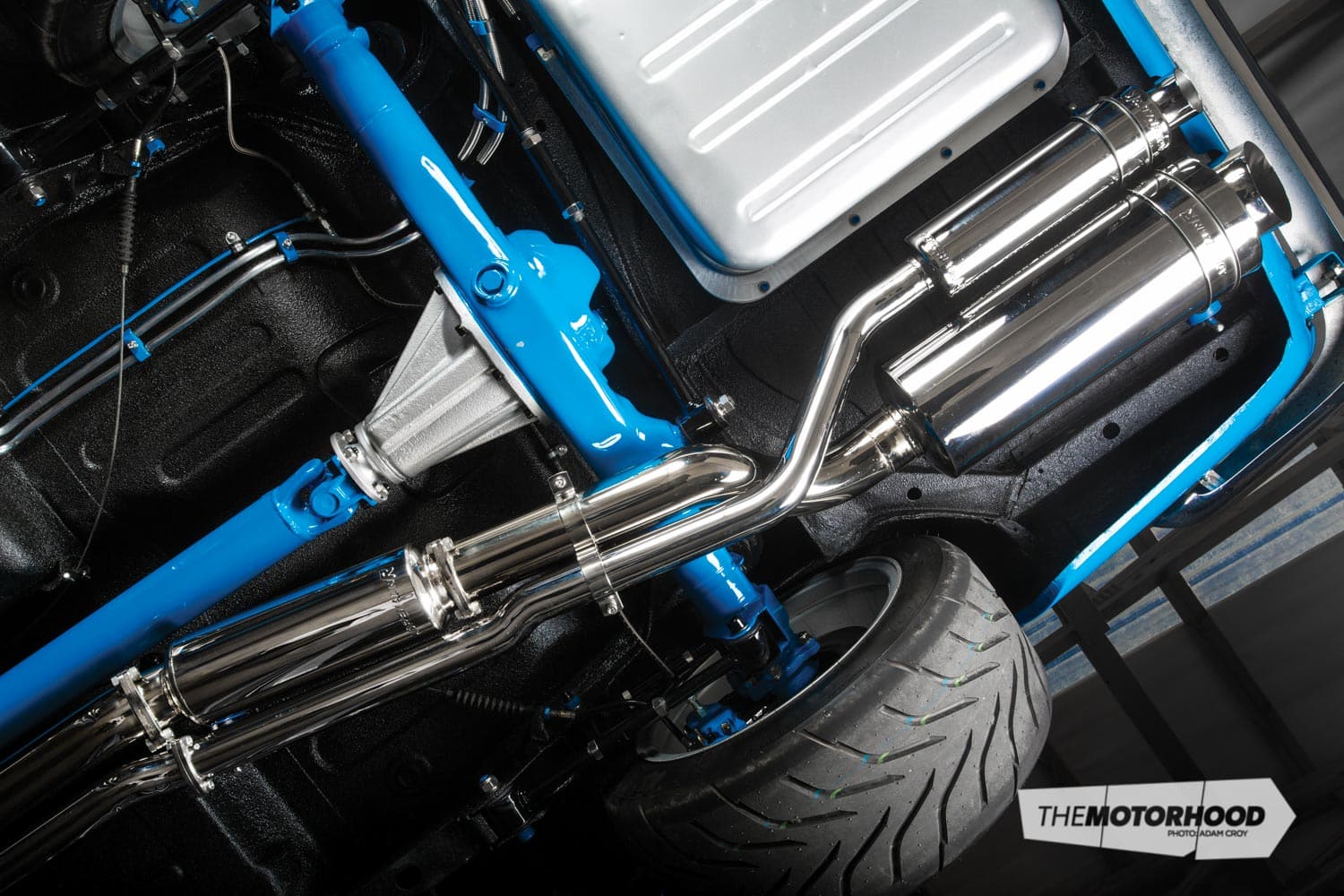

With the driveline sorted, Tim and the Raikes brothers had been scheming up plenty of custom work to carry out. This included the dual exhaust system, as Tim explains, “Bergen’s the main guy, we just started smashing around ideas. I always wanted to run the screamer pipe to the rear, and it sort of just snowballed from there. It actually took just under 50 hours to make the exhaust and 30–40 hours polishing it.” The detail put into it even extended to custom rotor-shaped flanges, and removing all the welds from the AdrenalinR rear mufflers for both systems.

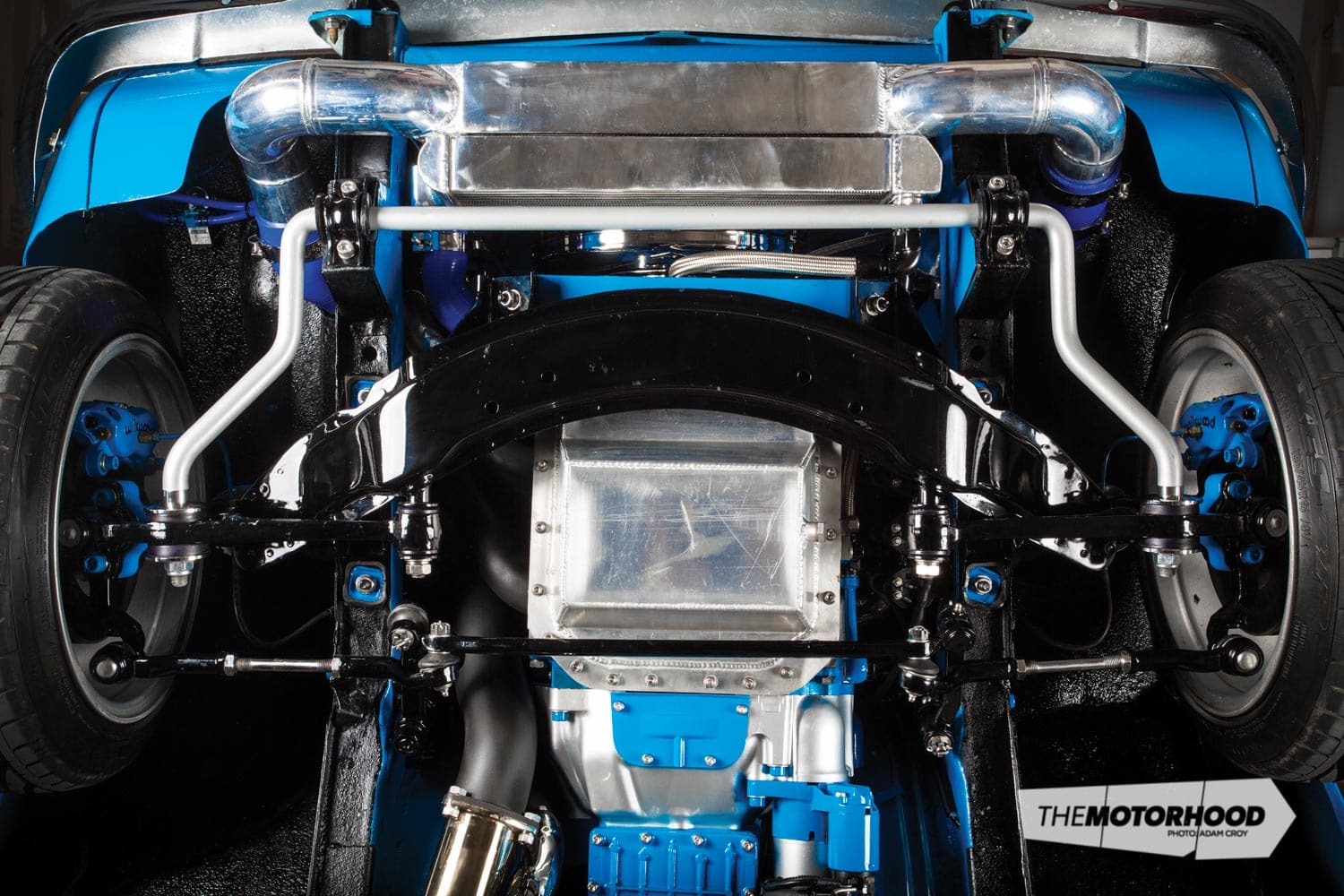

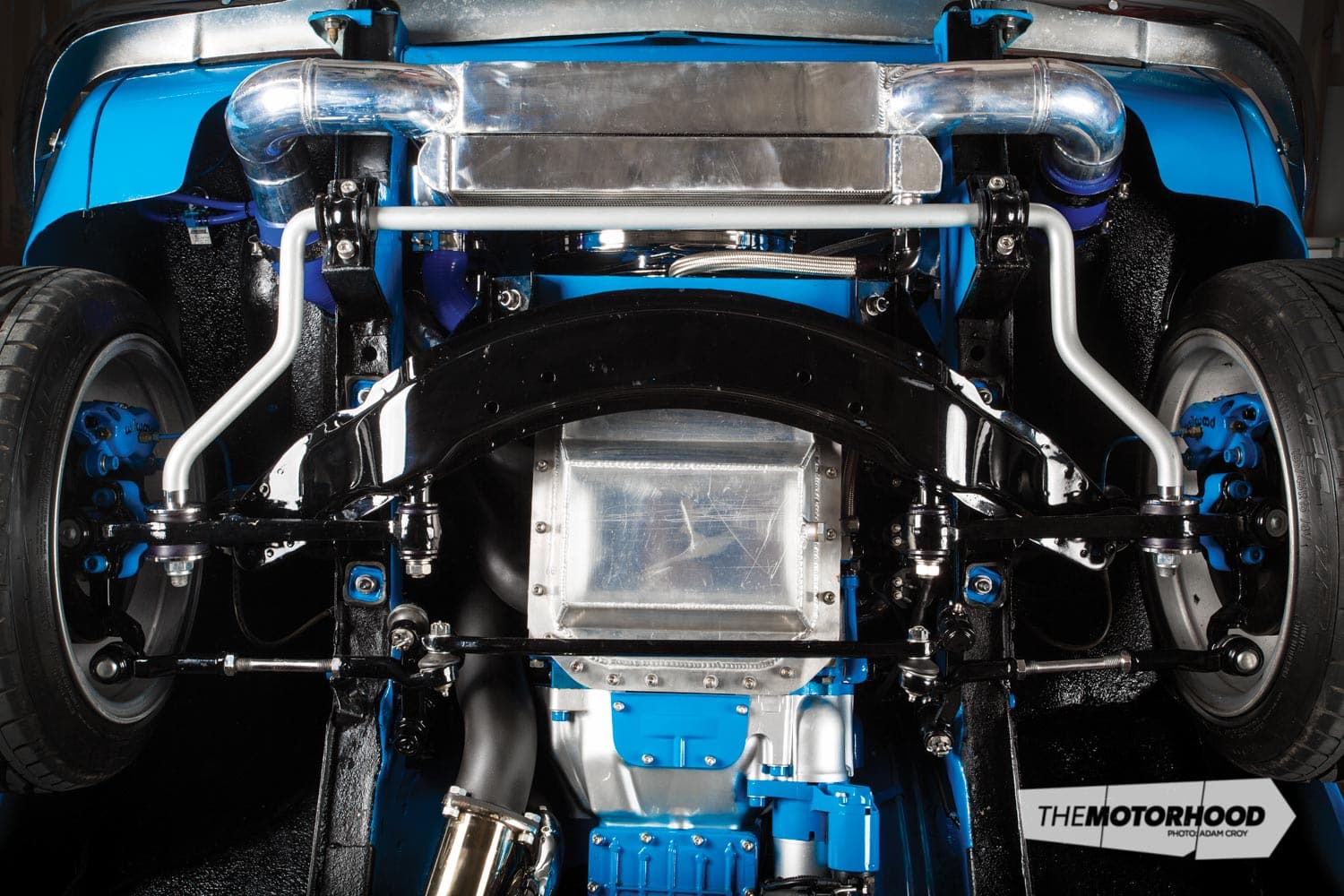

This OCD detailing carried on throughout the undercarriage. Tim and a few mates, who he bribed with free KFC, sorted the unenviable task of removing all the underseal and any brackets that weren’t needed. Then, any component that was bolted back on was either painted, polished, or custom made, if it wasn’t up to Tim’s exacting standards. For parts like the suspension castle nuts and swaybar washers — where your common, black components would usually suffice — Tim wasn’t happy that they would be mismatched, so had friends at Reid Machining custom make new ones from stainless. All up, he spent over $1500 on nuts and bolts alone.

Although it was in okay condition, the paint was showing its age, so Tim had another local, Baxter, respray 80 per cent of the shell. Tim admits he got it to a point where the build began to be a little obsessive, and thoughts of not driving it started to creep into his head. Thankfully, these didn’t last long. “I did have a small stage of thinking I might not drive it, but realistically, I couldn’t not. Last week I drove it for a wedding and picked up some people, and there were 100 people outside the pub with their cameras out. They were all city slickers, and just couldn’t believe a car like that could come from a small town like it has. Stuff like that makes me want to get it out, you know. I don’t think it will be that hard to clean underneath. Sure, you are going to get a few stone chips, but touch-up paint will have that sorted. The exhaust is a work or art, but if I do get a couple scrapes on it, its not like I can’t replace a piece.”

With the RX-2 now road legal, we’re glad that Tim isn’t shying away from driving it. After getting some heat cycles through the fresh engine, he’ll be adding in some boost, at which point we will really get to see what this home-built car can do — not that what this group of highly motivated and very talented young guys has produced isn’t proof enough that the import scene is in good hands. But, hey, frying some tyres and running a 10-second pass will just be the icing on the cake for this detail devil.

1974 Mazda RX-2

Want to learn more about achieving an award-winning chrome finish? Keen to grab a similar set of mufflers for your car?Want to know who’s responsible for the suspension castle nuts and swaybar washers?

Engine

- Model: Series 5 13B, 1300cc, 2-rotor

- Block: PPRE bridge-port plates, skimmed rotors, 3mm race apex seals, high-rev modified stationary gears, flowed oil galleries, S5 rotor plates, PPRE dowels, PPRE custom sump

- Intake: Simota air filter, three-inch intercooler piping, silicon joiners

- Exhaust: Custom three-inch polished stainless system, custom rotor-shaped flanges, AdrenalinR muffler

- Turbo: Custom Master Power T70, steam pipe manifold

- Wastegate: Turbosmart Pro-Gate 50mm, two-inch polished stainless full-length exhaust, AdrenalinR muffler

- BOV: TiAL 50mm

- Fuel: Bosch 044, Carter lift pump, upgraded injectors, custom fuel rail, 8mm fuel lines, Turbosmart regulator, Speedflow AN fittings, original fuel tank

- Ignition: MSD leads, Bosch coils, MicroTech ignitor

- ECU: MicroTech LTX8

- Cooling: Fenix radiator, custom hand-cut fan shroud, 14-inch fan, Fenix oil cooler, high flow thermostat

- Extra: Turbosmart E-Boost, de-loomed and shaved engine bay, custom oil catch can, polished stainless heat shroud, custom CAS cover, custom rotor-shaped T-bolt clamps, dome or cap screws used throughout, polished everything, solid engine mounts

Support

- Struts: (F) Koni custom coilovers, adjustable dampers, (R) custom KYB struts

- Springs: King springs

- Brakes: Wilwood master cylinder, custom brake lines, custom stainless brake pins, PPRE brake brackets, Wilwood four-piston calipers

- Other: Whiteline sway bars, Toyshop camber plates, Superpro bushes throughout, adjustable four-link rear, aftermarket bump stops, custom stainless castor shims, custom stainless sway bar washers, new tie rods and bushes, custom stainless castle nuts, custom stainless nuts used throughout, detailed everything

Exterior

- Paint: Respray in Bionic Blue by Baxter (Kevin Barkla car painters)

Shoes

- Wheels: (F) Rota Grid V 15×8-inch, (R) Rota Grid V 15×9-inch

- Tyres: (F) Toyo T1R 195/45R15, (R) Toyo R888 225/45R15

Drive

- Gearbox: Series 4 RX-7 five-speed

- Clutch: Tilton twin plate

- Flywheel: Custom

- Diff: Shortened Hilux housing, 4.3:1 Hilux LSD, shimmed LSD, custom axles

- Extra: Wilwood master cylinder, custom reservoir cap, detailed and cap screwed

Interior

- Seats: Evo VI Recaro, reupholstered to mimic factory RX-2 seat

- Steering wheel: Sportline

- Instrumentation: OEM

- Ice: JVC head unit, four-inch speaker

You can buy a copy of the magazine this article was originally published in here: