“The toughest import street car ever built!”

After 30-plus years of people worldwide building heavily modified Mazda rotaries, you need to think well outside the box if you plan something new and fresh that’ll stand out from the crowd. Although, to say it has all been done would be as foolhardy as US Commissioner of Patents Charles H Duell was when he famously proclaimed that the US Patent Office should close its doors in 1899, as there was nothing left to invent … because there are people like Alex Sigley and Warren Overton who are willing to push the limits of what is known to be possible, all in the pursuit of horsepower.

What they’ve come up with was more than a stroke of genius, it was a world first. After 18 years of ownership Alex had grown tired of his 525kW 13B turbo-powered RX-4 coupe, a car that NZPC had featured twice before. He wanted to do something new, so he called on his business partner and long-time friend, Warren Overton, at Pulse Performance Race Engineering.

Warren says, “When Alex came to me and said let’s do something really different with the RX-4, we were originally looking at doing a four-rotor, or maybe a four-rotor turbo, but then it would have been just another four-rotor. The next logical step was to go a five-rotor, but after talking with Jeff from Precision Engineering, the man responsible for machining the E shafts and working out that a six-cylinder firing order should in theory work, we decided to build the world’s first six-rotor.”

It was late in 2011 when the Pulse Performance Race Engineering (PPRE) team announced their plans to the world with a few images of a dummy block sitting in the chopped-up RX-4. The images caused quite a stir on the worldwide web, and as Warren puts it, their Facebook page went from zero to hero overnight. Everyone seemed to have a strong opinion on the build, with many sceptical it would even run, and believing the image was nothing more than a publicity stunt by the Wanganui-based workshop. But this couldn’t have been further from the truth. Although a number of unknowns surrounded the project, Warren was not only determined, but certain they could make it work, and work well.

The six-rotor only weights 50kg more than your run-of-the mill Nissan RB six-cylinder. But with half the engine sitting north of the strut towers, it will never claim lap records. Then again, it was never built for that, it’s a street rod through and through

The biggest hurdle with building multiple rotor engines is being able to assemble the block in the correct order. A traditional one-piece eccentric shaft was out of the question. Warren used the same design principles as the four-rotor cranks in Mad Mike’s RX-7 and the Hujis sprint boat (a design he also came up with). Essentially the 6B crank is an elongated 13B shaft that incorporates the two centre lobes. The remaining four lobes bolt on, two each side, to total six. When it came to balancing the rotating assembly the team had to fabricate temporary rear counterweights that attach to the splined E shaft. When they had the balancing spot on, a final set was produced and those first ones became nothing but useless paperweights.

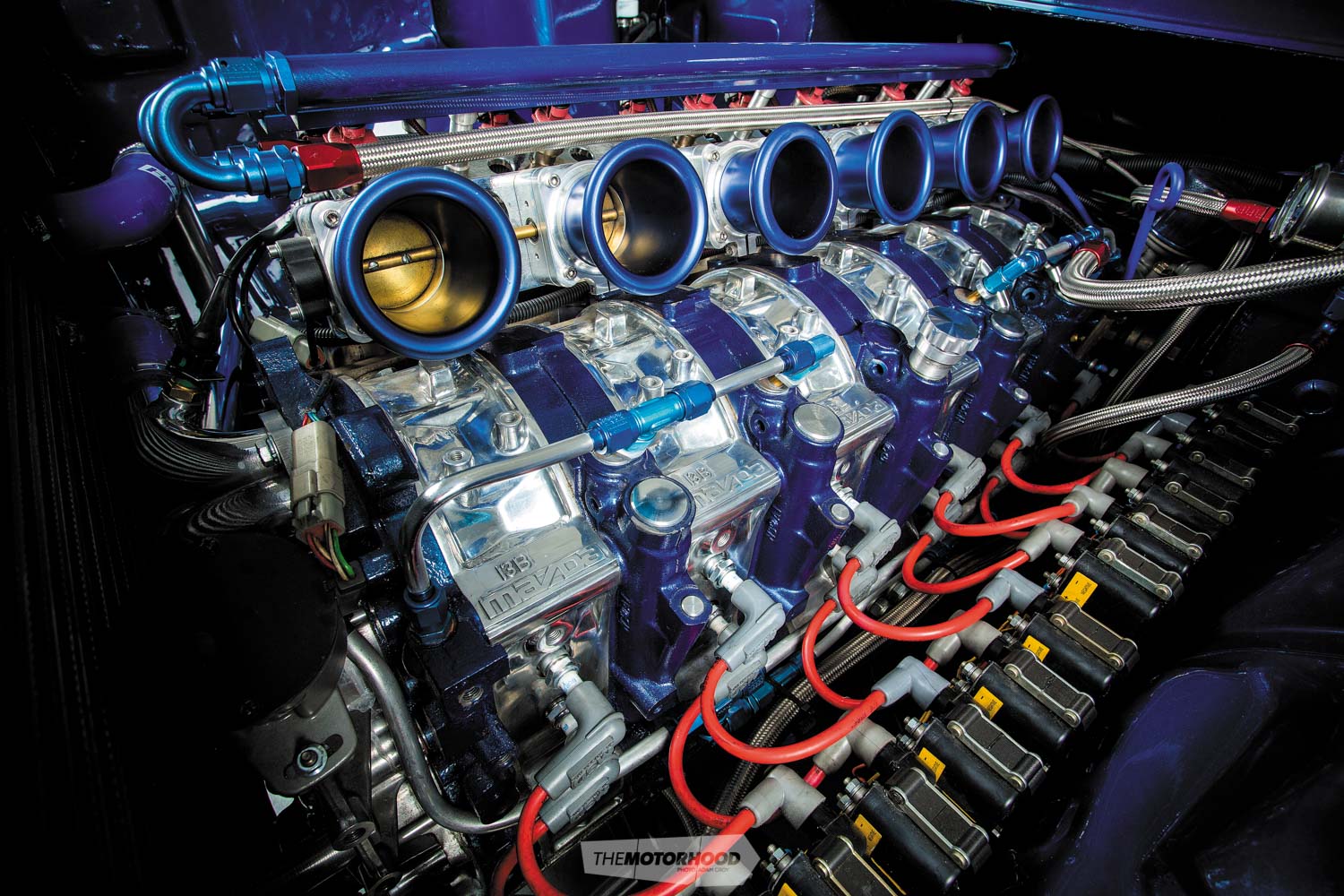

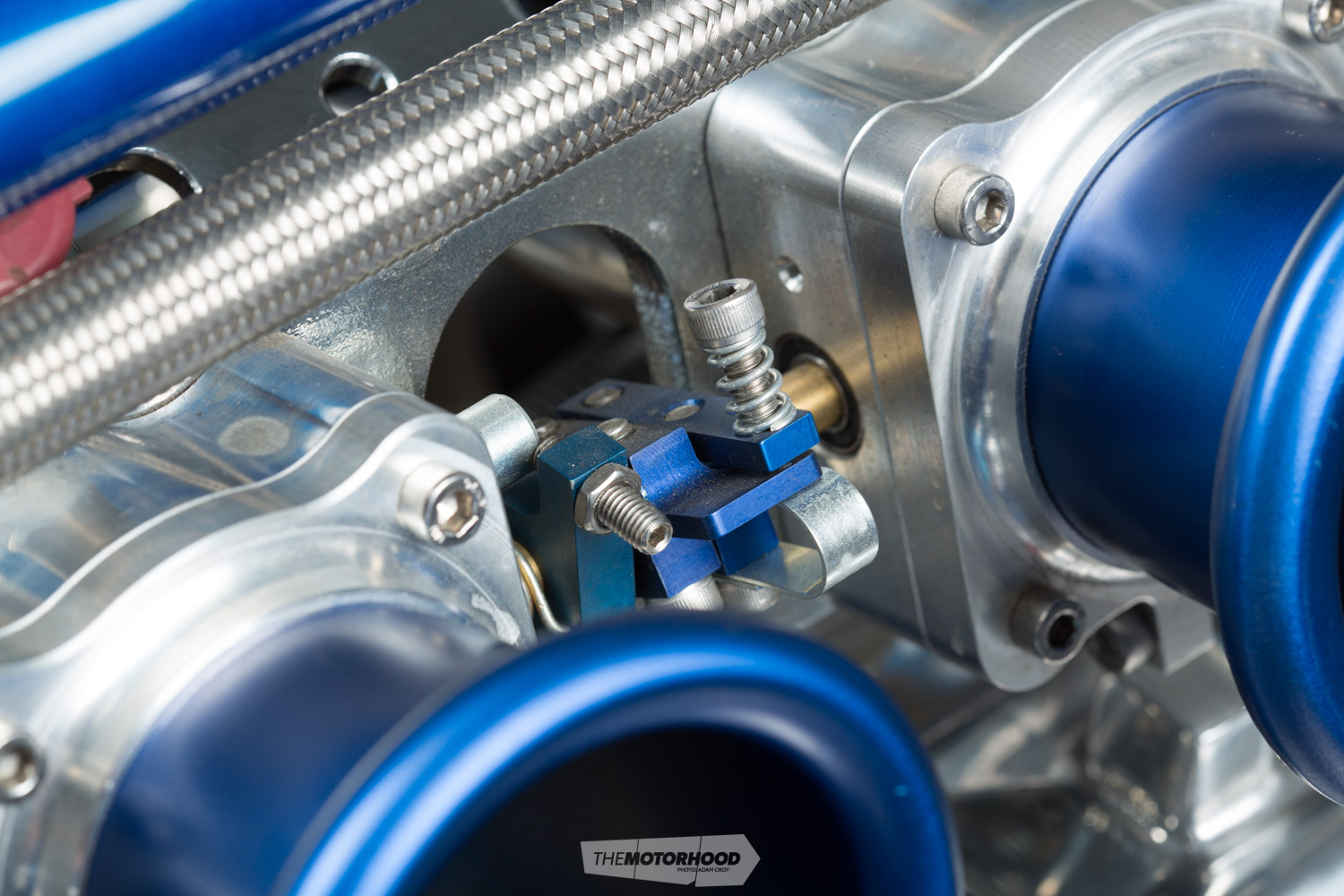

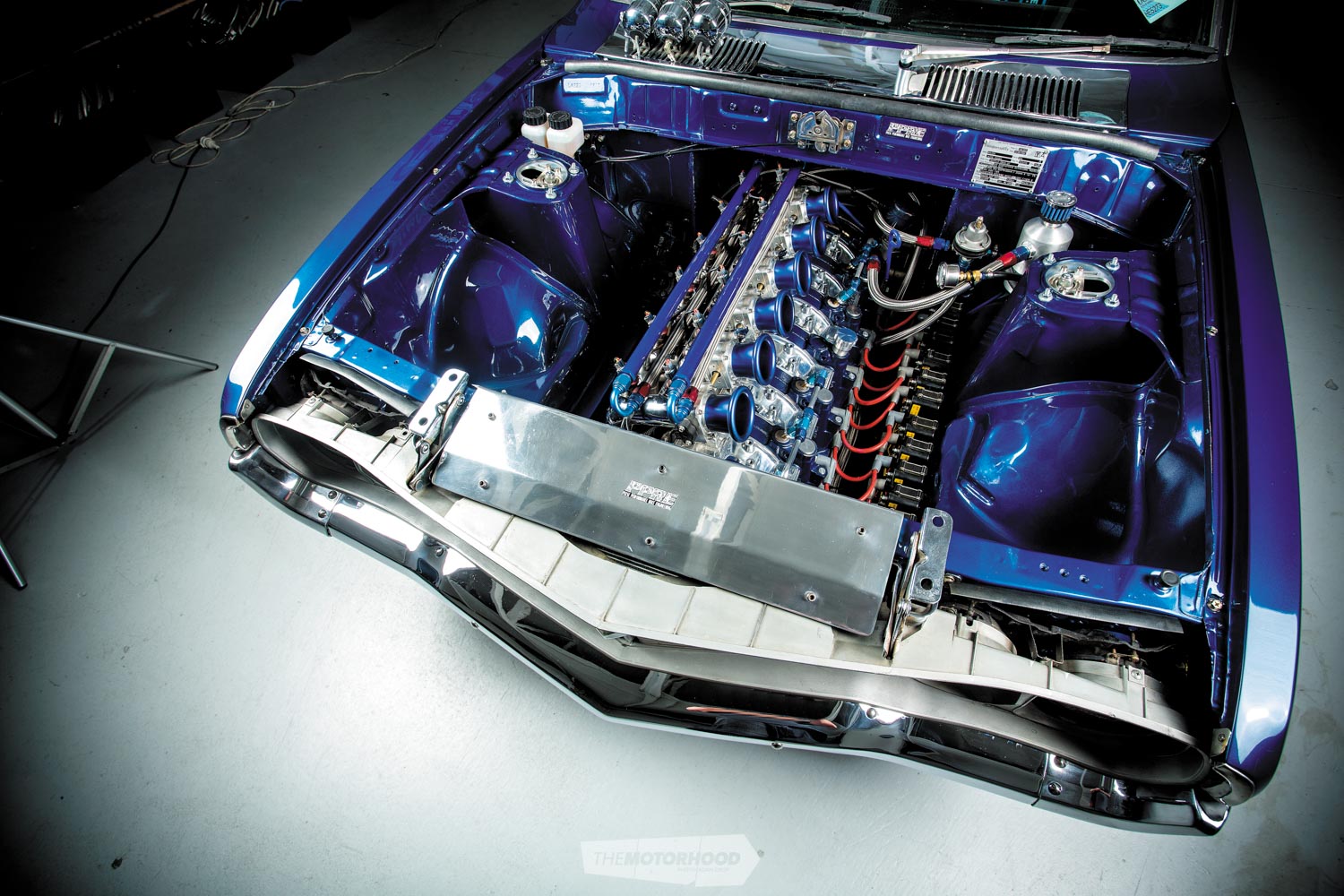

For ignition and fuelling, a call was placed to Australian-based MicroTech which was more than happy to get behind the project, and build a custom ECU to suit the six-rotor. With 12 injectors, six throttle bodies, 12 spark plugs and 12 coils, no off-the-shelf unit would cope. So MicroTech built a custom LT-16c with twin X6 igniters firing a spark plug every 60 degrees of crank rotation. The firing order is the same as any six-cylinder engine on the market.

It was mid 2012 when the 6B was finally pieced together on the engine stand, all wired up and ready to fire. An announcement on the PPRE Facebook page promising a video had guys glued to their screens the world over, some even staying up for days on end in anticipation of that first glimpse. Needless to say it was a tense time around the shop when the start button was hit for the first time. There was a lot of money at stake, and the world was watching. “The biggest unknown was the fact of harmonic imbalance, no one was sure whether it would just grenade itself on start-up from an imbalance, this was something that would be a start-it-and-see situation.”

At a cost of $14,000 to machine the five-piece crank and all those housings and rotors it would have been a costly trial if it hadn’t worked. But that is the game you play when building a world-first, the concepts ‘off the shelf’ or ‘tried and tested’ don’t apply. Thankfully the initial start-up went perfectly, and after a few fuel adjustments on the laptop Warren was ready to free-rev it, spinning the rotors to 9000rpm with giant flames bursting out the exhaust, creating a video that went viral on the internet and put to rest all those questions about the engine’s ability to run. The small group of guys who hovered around the 6B had just witnessed the birth of a monster.

But of course that was only half the project, the actual car was still far from ready to receive the engine and cruise Wanganui’s main drag, the original inspiration for the build, as Warren explained. “Alex and I are both members of the very active local hot rod club, not a day goes by that you don’t see a tough hot rod cruising the street. That is what we wanted the RX-4 to be, an extremely tough hot rod.”

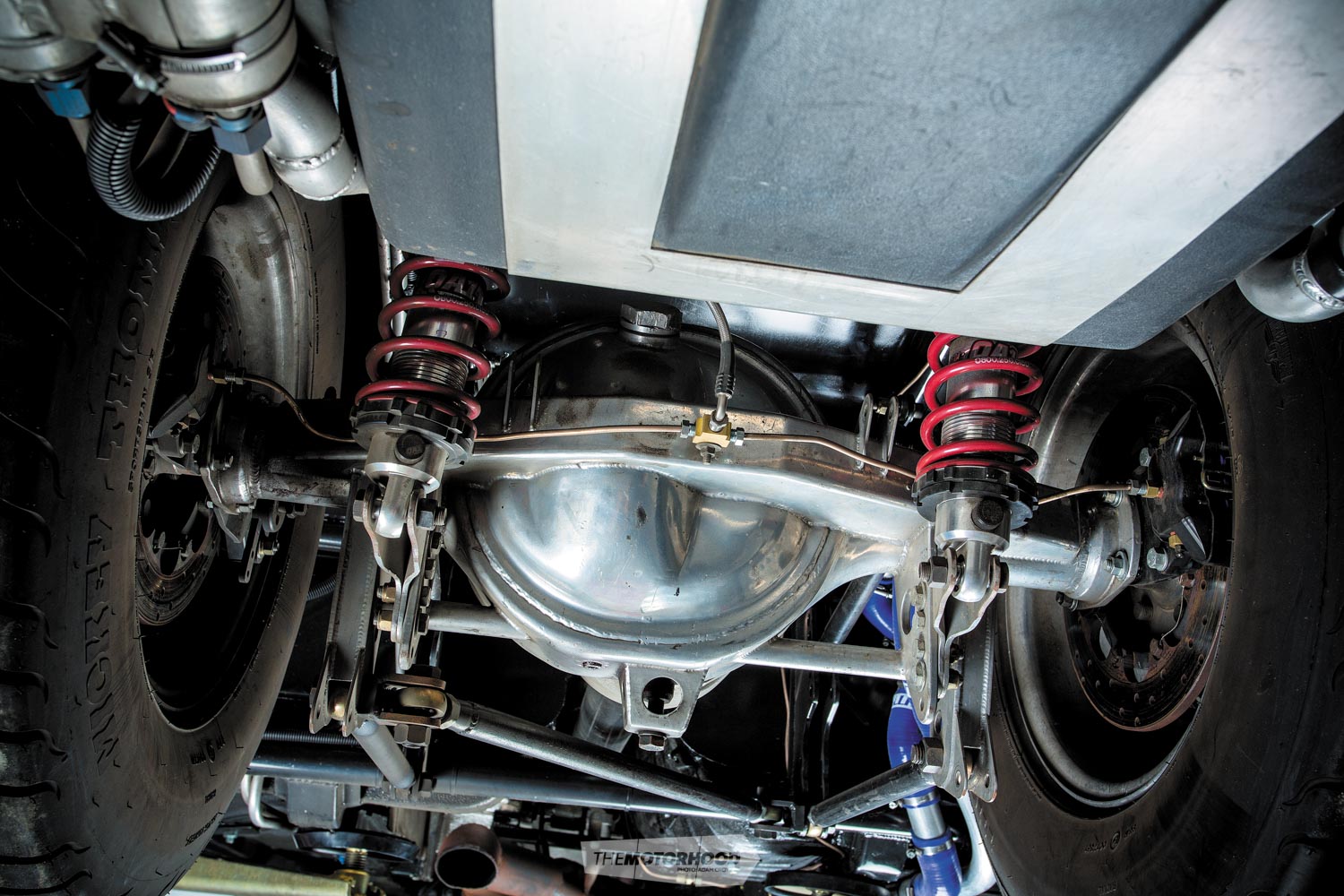

And what hot rod would be complete without a set of big 15×12.5-inch rims wrapped in sticky street-legal Mickey Thompson rubber. Getting them in there required some serious cutting of the chassis, and removing everything behind the B-pillar to make way for the new chassis clip that the PPRE team was building to house the nine-inch diff with alloy Moser head, 35-spline gun-drilled axles, and the rose-jointed five-link kit. They also built a complex NZDRA-spec roll cage to tie everything into the existing chassis.

Alex tells us that the even when you drop the clutch at 9000rpm in third gear, the large Mickey Thompson street ETs find grip and slingshot the car forward. To help keep keep the RX-4 pointed straight the front wheels run a massive eight degrees of negative camber, forcing the car to centre itself

With the body nearing completion the unveil date was set — the 2013 V 4&Rotary Nationals. The PPRE team worked nearly around the clock to get the RX-4 to driving state. Alex’s first drive was actually off the trailer and into the show hall. If you were present that day or during the many start-ups the following day of the show ’n’ shine, you’ll know it’s a noise no one will forget in a hurry. Ear-piercingly loud was an understatement, forget the F1-like scream of a four rotor, the 6B produces a noise that’s pure aggression, the kind to make grown men block their ears, and run.

Though the car was now running, nothing could prepare Alex for the initial test drive. “It was just instant power, it made me anxious for the next few days after driving it. The power delivery was animal and nothing like the turbo. Instant power was just right there whenever you pressed the throttle.”

He isn’t joking when he says instant, with over 220kW (300hp) and 650Nm (480lb/ft) of torque just off idle; and the power keeps climbing to over 600kW at 9000rpm. The torque curve peaks at 5000rpm where it’s making 759Nm as it flattens off, similar to that of a high-power V8. And with a new exhaust system soon to go on, Warren hopes to raise the torque a little further.

So what’s next for the toughest import ever to hit the streets of New Zealand? Alex is eager to get the cert plate on there and cruise it, and even plans to attend hot rod events like Kumeu and Beach Hop where even die-hard V8 guys will have to block their ears. This ain’t no uncapped set of headers on your small-block Chev, mate, this is the world’s only 6B PP!

It may not be the only one for long, as now it’s proven to work, the PPRE phone has been running red hot with interested parties wanting to shoehorn 6Bs in all sorts of vehicles, and Warren dreams of sticking one into a jet sprint boat.

When Alex was 14 and carried out the first engine conversion on this Mazda in his back yard, he couldn’t have imagined the RX-4 evolving into the car it would eventually become

During the photo shoot there was one burning question we had to ask Warren. Would it be possible to throw boost through one of these? “We will definitely turbo one in future and it will likely be in the RX-4, we will run it NA for a while and if it handles the punishment Alex dishes out, that would likely be the next step, probably twin-turbo.” So if you think 600kW from a normally aspirated street-driven rotary is insane, wait until we see a figure capable of shutting dynos down. Just another world first from little old New Zealand!

Alex Sigley

Age: 32

Location: Wanganui

Occupation: Builder

Build time: 14 months

Length of ownership: 21 years

Thanks: Paul at NZ Performance, Jeff and the team at Precision Engineering, Tony at Tony Hughes Light Engineering, Pat and Dom at MicroTech

Heart

ENGINE: PPRE 6B, 4000cc, six-rotor

BLOCK: Lightened and balanced RX-8 rotors, PPRE apex seals, chromoly 6B five-piece eccentric shaft, externally oiled stationary gears, 46mm peripheral-ported housings, Series 6 windowed rotor bearings, custom splined counterweight, custom through-bolt set

INTAKE: Custom PPRE tapered steel intake manifold, 55mm EFI hardware throttle bodies

EXHAUST: 6-2-1 headers, large single muffler yet to come

FUEL: Two Bosch 044 main pumps, Bosch Motorsport fuel filters, Malpassi fuel regulator, 12x 550cc injectors

IGNITION: 12 Bosch HEC coils, PPRE custom MSD leads, two MicroTech X6 igniters

ECU: Modified MicroTech LT-16c

COOLING: Twin rear-mounted Redline Performance alloy radiators, custom front-mounted alloy radiator, Davies Craig alloy rear-mounted water pump

EXTRA: Auxiliary Peterson oil pump, Series 4 RX-7 engine mounts, braided lines throughout, oil catch can, direct oil feed modification

Drive

GEARBOX: Tremec TK600 five-speed

CLUTCH: Tilton 184mm (7.25-inch) triple-plate

FLYWHEEL: Custom 3.1kg (7lb)

DIFF: Strong-backed housing, Moser alloy nine-inch head, Moser gun-drilled and star-flanged 35-spline axles

Support

STRUTS: (F) Koni Inserts, modified RX-4 struts, 600lb springs; (R) QA1 adjustable coilovers

BRAKES: Tilton swing-type pedal box (F) Wilwood four-pot calipers, Series 5 RX-7 rotors, Wilwood Street Performance pads (R) Wilwood two-pot calipers, Wilwood rotors, Wilwood handbrake calipers

EXTRA: PPRE rose-jointed five-link, PPRE custom rear sway bar, Toyshop engineering camber plates

Shoes

WHEELS: (F) 15×5-inch Weld Alumstar; (R) 15×13-inch Weld Alumstar

TYRES: (F) Mickey Thompson Sportsman S/P front runners ( R) Mickey Thompson 26x15x15-inch E/T Street

Exterior

PAINT: Custom PPG midnight pearl blue

ENHANCEMENTS: Factory

Interior

SEATS: STA

STEERING WHEEL: Saas

INSTRUMENTATION: Factory

EXTRA: PPRE NZDRA spec roll cage, enlarged gearbox tunnel, sheet metal tubs , raised passenger seat to allow for custom muffler

Performance

POWER: 606kW (813hp) at 8800rpm, 759Nm of torque at 5000rpm at the wheels

This article originally appear in NZ Performance Car issue No. 200 (back in 2013). You can grab yourself a full copy of the mag at the link below: